Grey Yarns

Multi-Locational, Vertically Integrated Operations

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

GTN Industries Ltd, is a multi-location, vertically integrated - fibre thru’ fashion company. Its Grey Yarn spinning division produces international quality yarn from its strategically located plants at Medak in Telangana; Nagpur and Baramati in Maharashtra. With combined spindleage of 1,45,200, the Company produces top quality grey yarn from premium cotton sourced from USA, Egypt and India in normal and organic variants, meeting the challenges of time and technology.

GTN Industries’ vertically integrated manufacturing set-up produces fine and superfine cotton grey yarns offering a unique One-Stop-Shop to those looking for an operationally strong and reliable manufacturer.

Superior Technology Advantage

Slide title

Chitkul - Spinning & Doubling Units, Hyderabad

Button

Slide title

Grey Yarn Spinning Unit, Nagpur, Maharashtra

Button

Slide title

GIL Grey Yarn Spinning Unit, Baramati, Maharashtra

Button

Slide title

Staff Quarters_GIL Grey Yarn Spinning Unit, Nagpur, Maharashtra

Button

Slide title

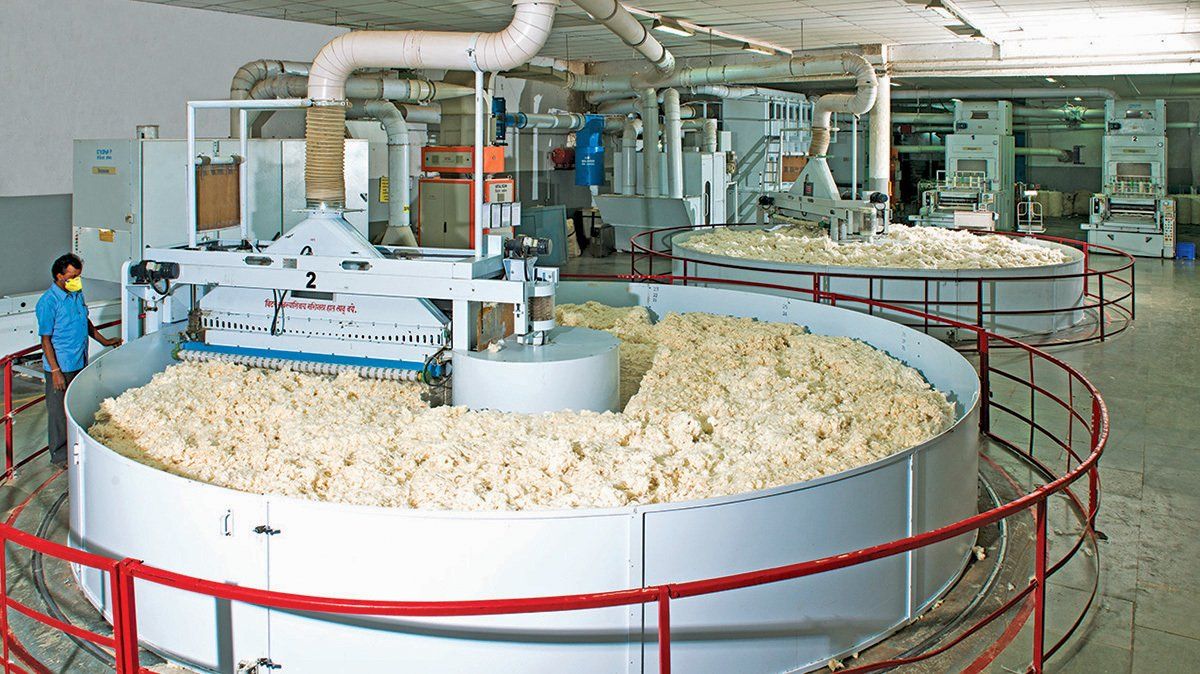

Automatic Bale Plucker

Button

Slide title

Truetzschler Blow Room with Blendomat

Button

Slide title

Truetzschler Carding

Button

Slide title

Truetzschler Carding

Button

Slide title

LMW Draw Frame

Button

Slide title

LMW Lap Former

Button

Slide title

LMW Speed Frame

Button

Slide title

Reiter LMW High Speed Comber

Button

Slide title

Oerlikon Saurer TFO

Button

Slide title

Muratec Link Coner, Baramati Unit, Maharashtra

Button

Slide title

Muratec Link Coner, Chitkul Unit, Hyderabad

Button

Slide title

Schlafhorst Autoconer, Chitkul Unit, Hyderabad

Button

Slide title

LMW Speed Frame

Button

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Oerlikon Saurer Cheese Winders

Button

Slide title

Peass Schlafhorst Soft Package Winders

Button

Slide title

GIL Medak Spinning Unit - QC Lab

Button

Slide title

GIL Medak Spinning Unit - QC Lab

Button

Slide title

Uster HVI Spectrum

Button

Slide title

Uster Tensorapid 3

Button

Slide title

Uster Tester 5

Button

Slide title

Uster Classimat Quantum

Button

Slide title

GIL Medak Spinning Unit - QC Lab

Button

Slide title

Yarn Cartons ready for despatch

Button

Slide title

UV Light Check of Yarn

Button

Slide title

Xorella Yarn Conditioning

Button

Slide title

Grey Yarn ready for despatch

Button

Slide title

Yarn Palletisation

Button

State-of-the-art Equipment

- Blow Room Equipment from TRUETZSCHLER & LMW

- Carding Equipment from TRUETZSCHLER & LMW

- Combers from LMW & REITER

- Ring Frames and Draw Frames from LMW & KTTM

- Compact from SUESSAN

- Auto Coners from SCHLAFHORST & MURATECH

- Yarn Conditioners from XORELLA

- Twisting Machines from VOLKMANN & SAVIO

- Waste Collection Equipment from LUWA

- Testing and Quality Control Equipment from ZELLWEGER USTER, CLASSIMAT & SPINLAB

Impressive Spindleage

GTN Industries is constantly upgrading its spindleage ever since its inception, in tune with the growing market demands and the Company’s vision to maintain its leadership position. This is also complemented by strategically acquiring new spinning units and augmenting them with modern machinery and ensuring their compliance to Quality, Health, Safety, Environment and Energy Management best practices and Systems.

| Unit / Location | Existing Spindleage |

|---|---|

| Medak | 55,248 |

| Nagpur | 41,856 |

| Baramati | 36,672 |

| Total Spindleage | 1,33,776 |

Slide title

GIL, Medak Unit - Quality Management System Certification

Button

Slide title

GIL, Medak Unit - Environment Management System Certification

Button

Slide title

GIL, Medak Unit - Ocupational Health & Safety Management System Certification

Button

Slide title

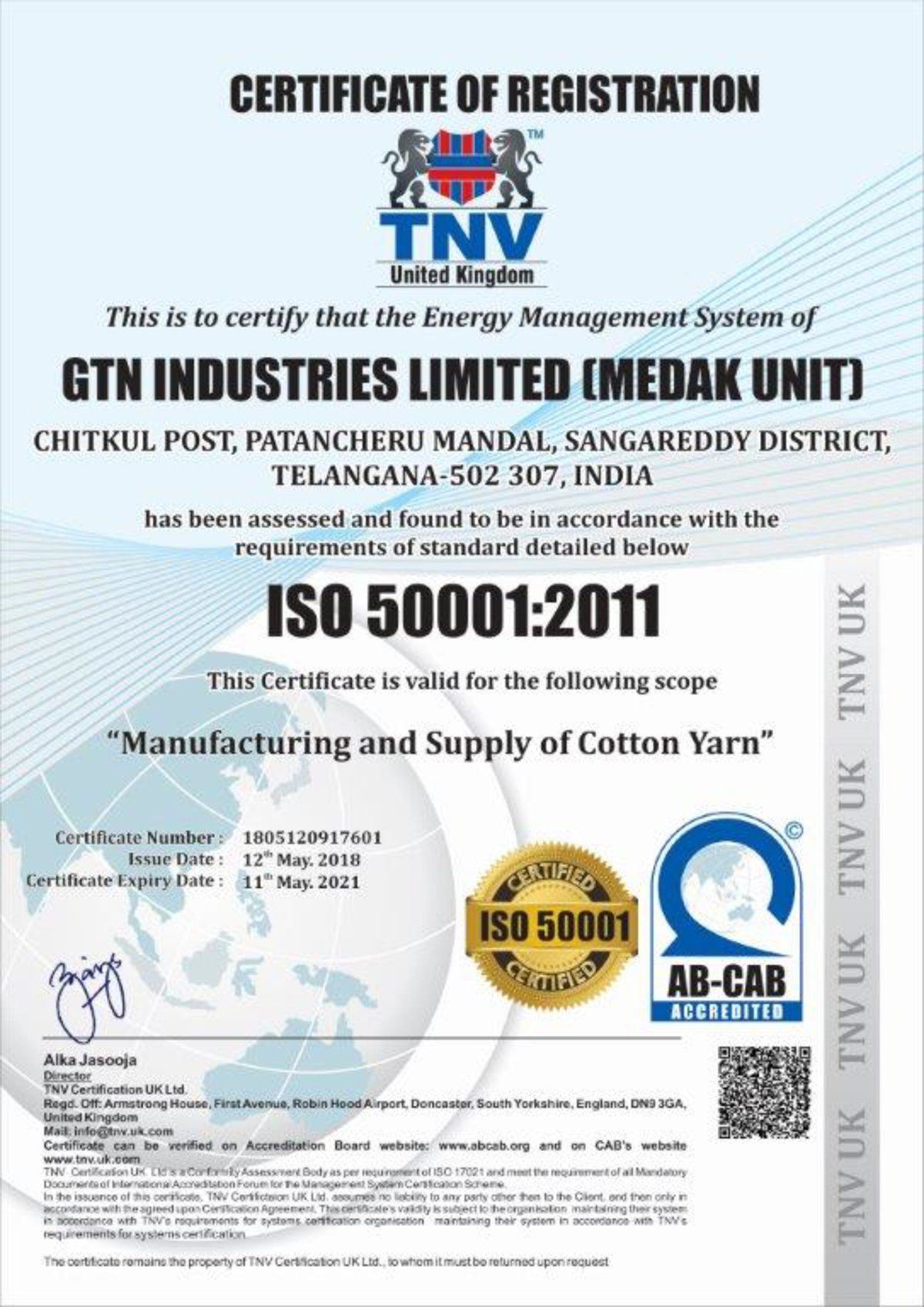

GIL, Medak Unit - Energy Management System Certification

Button

Slide title

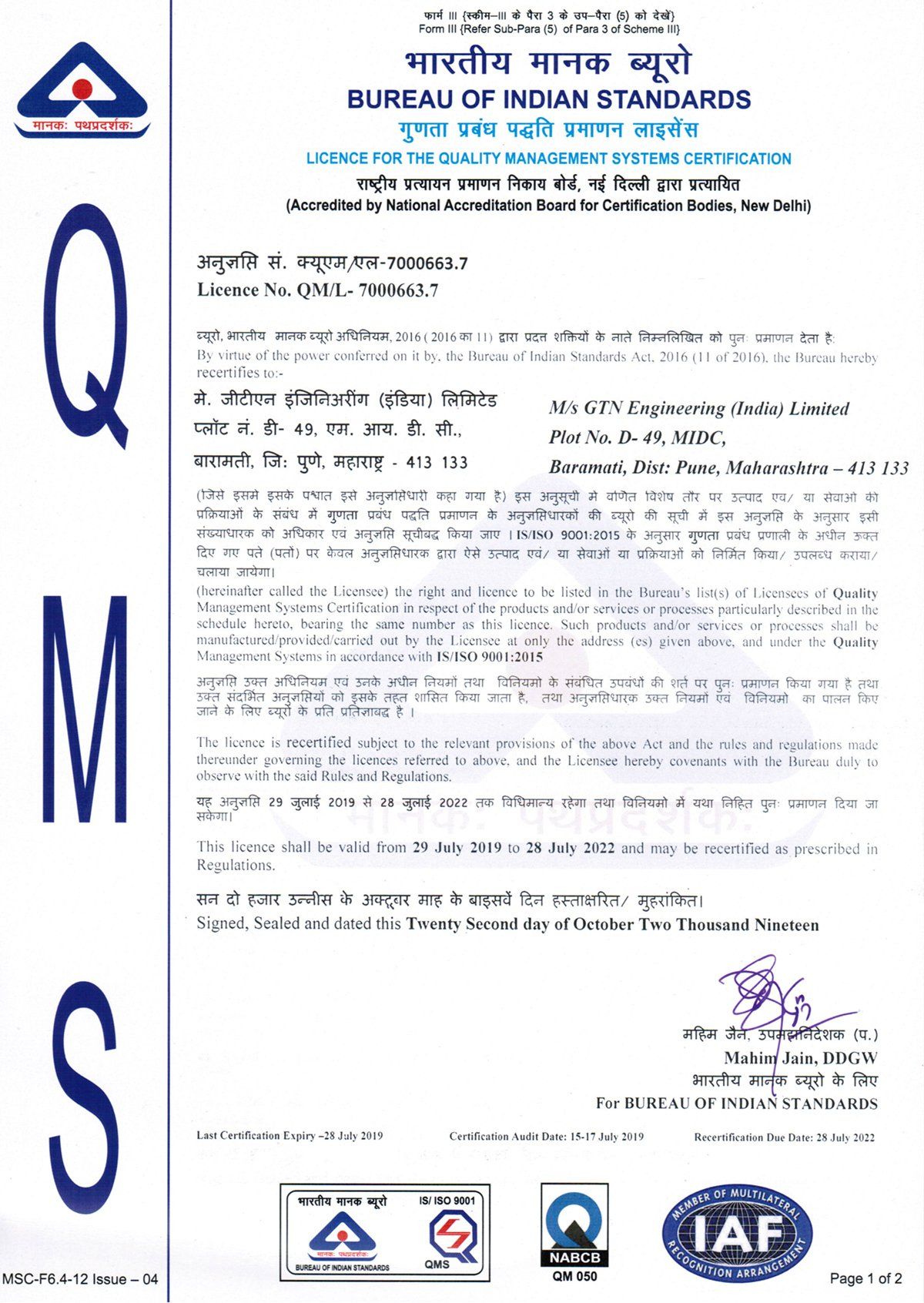

GTNE(I)L, Baramati Unit - Quality Management System Certification

Button

Slide title

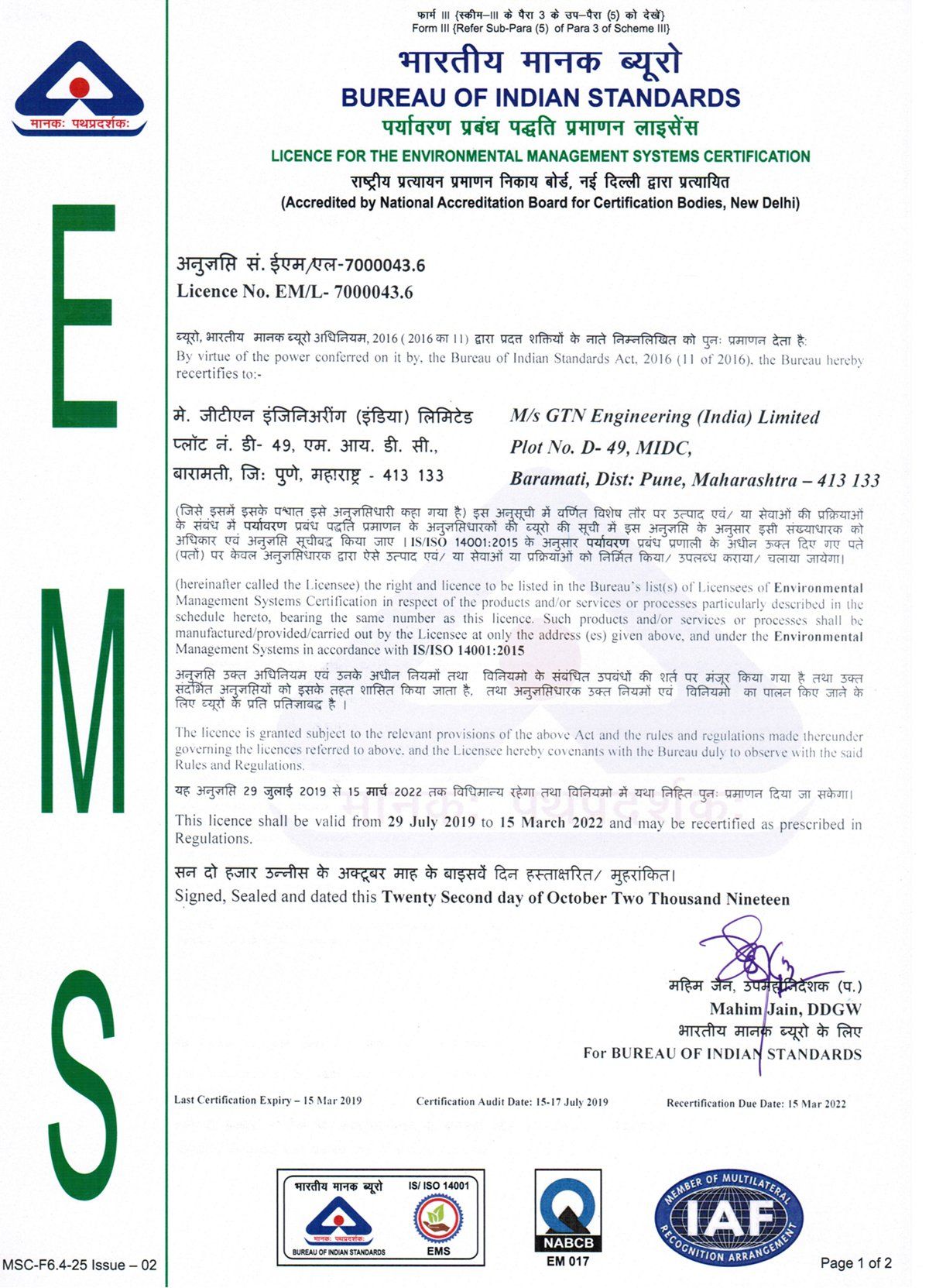

GTNE(I)L, Baramati Unit - Environmental Management System Certification

Button

Slide title

GIL, Nagpur Unit - Quality Management System Certification

Button

Slide title

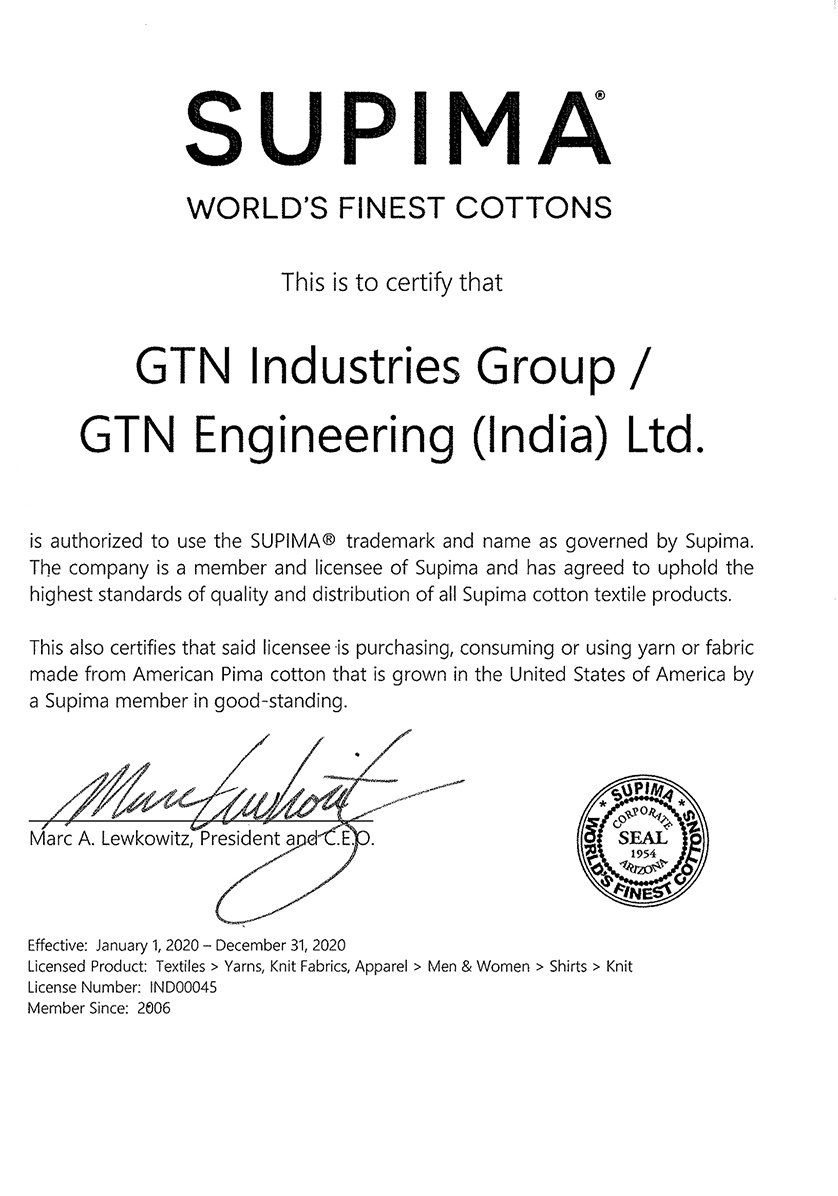

SUPIMA Certification

Button

Slide title

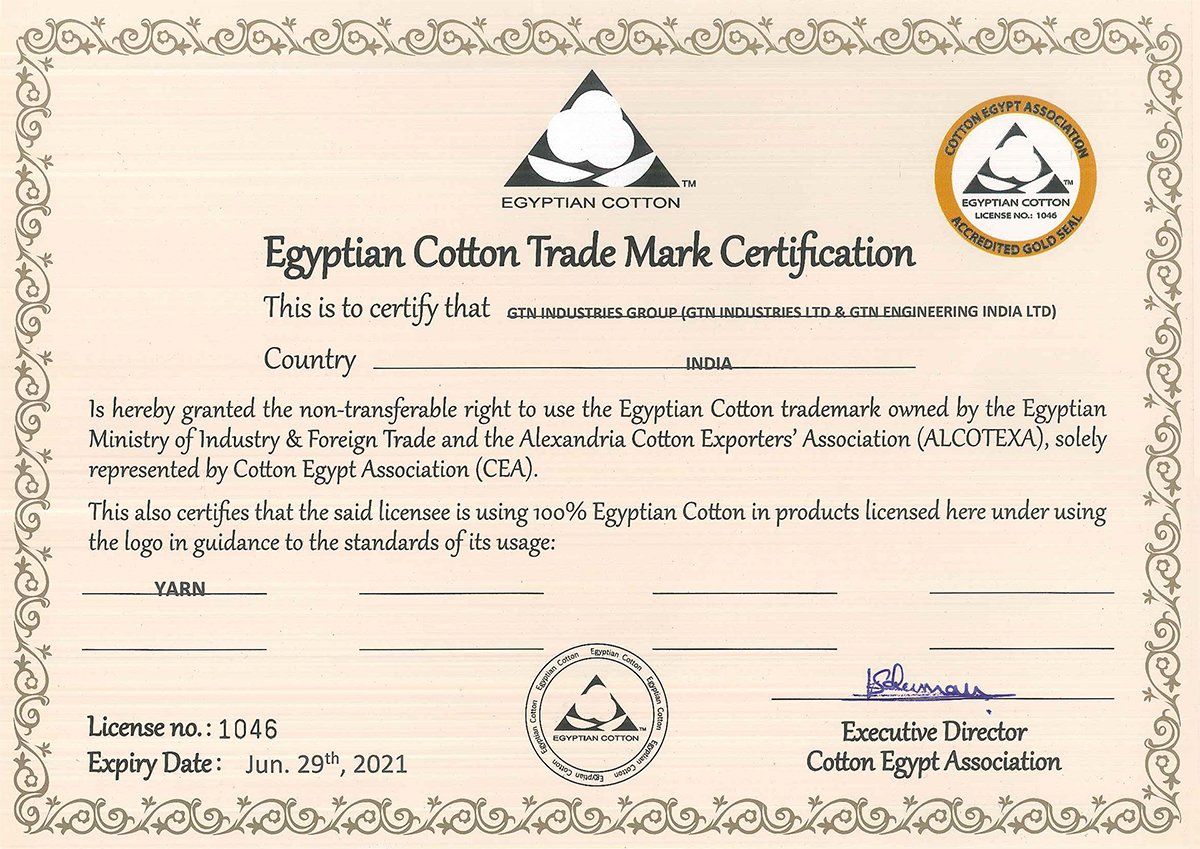

Egyptian Cotton Trade Mark Certificate

Button

Complete Range of Grey Yarns

With decades of expertise and excellence of meeting the discerning needs of niche clients world wide, GTN Industries - World Class Grey Yarn variants spun from :

Premium 100 % Supima Cotton

Contamination Free Cotton

- 20’s to 60’s in Single, Double, Compact & Gassed

Premium Egyptian Cotton

Premium Indian Cotton

- 20’s to 80’s in Single, Double, Compact & Gassed

. . . continue to make impressive contributions in the world of premium quality cotton yarn, fabrics and garments there after.